WELCOME TO MADURGA ENTERPRISE

CNC Machine , VMC Machine & VTL Machine

8000 SQ FEET Covered Area

3 WORKSHOPS

Computer Numerical Control (CNC) Machine

At Madurga Enterprise, we take pride in our state-of-the-art manufacturing facility equipped with advanced CNC machining centers and a highly skilled technical team. With four large CNC machines, we have the capability to produce complex and high-precision components that meet international standards of quality and performance.

Quality Assurance: Quality is at the core of our manufacturing process. Each component undergoes strict inspection using calibrated measuring instruments, surface testers, and gauges. We maintain detailed records for complete traceability and ensure every product meets client specifications.

Our Strengths:

- Advanced CNC Machines with Skilled Operators

- Experienced Engineering Team for Design & Process Optimization

- Dedicated Quality Control Department

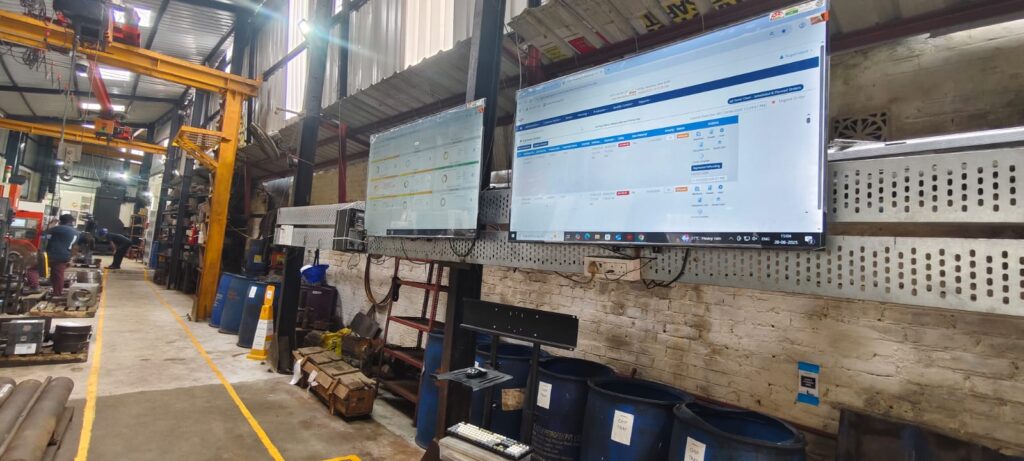

- Efficient Material Handling & Workflow System Capability for Custom Manufacturing as per Client Drawings

Vertical Machining Center (VMC) Machine

Our facility is equipped with advanced VMC machines that enable high-precision and high-efficiency machining for a wide range of industrial components. These machines form the backbone of our production unit, allowing us to achieve exceptional accuracy, surface finish, and dimensional consistency in every job.

Assured Quality:

Each part machined on our VMCs undergoes rigorous inspection to ensure dimensional precision and surface integrity. Our skilled operators and engineers follow strict process controls, ensuring top-notch results that meet or exceed customer expectations.

Key Advantages:

- High-speed and stable machining for complex geometries

- Superior surface finish and consistent accuracy

- Reduced production time with multi-operation capability

- Capability to handle both prototype and mass production requirements

- Precision machining as per customer drawings and specifications

Vertical Turning Lathe (VTL) Machine

Our Vertical Turning Lathe (VTL) machines enable us to handle large and heavy components with high precision and efficiency. Designed for heavy-duty turning operations, our VTL machines deliver exceptional accuracy, surface finish, and reliability—making them ideal for machining flanges, rings, and other cylindrical components.

Assured Quality:

Every job on our VTL machine is monitored through precise measurement and quality checks at every stage. Our commitment to precision ensures that each component meets exact customer requirements for performance and durability.

Key Advantages:

- Capable of handling heavy and large-diameter workpieces

- High rigidity and stability for superior machining accuracy

- Smooth surface finish with consistent repeatability

- Efficient setup and cycle times for faster production

- Skilled operators ensuring top-quality output

Grinding, Drilling & Shaping Machine

Grinding Machine

We are equipped with precision Grinding Machines that ensure accurate finishing and dimensional control of machined components. Our grinding facility helps achieve superior surface finish, tight tolerances, and perfect roundness — essential for high-performance industrial parts.

Drilling Machine

Our facility is equipped with high-precision Drilling Machines used for accurate hole making, tapping, and boring operations. These machines enable us to maintain perfect alignment, consistency, and dimensional accuracy across all types of components.

Shaping Machine

Our Shaping Machines are used for producing precise flat, angular, and contoured surfaces with high accuracy and smooth finish. These machines are ideal for machining slots, grooves, and keyways on various components.